The Artemis space missions will write a piece of space history and once again bring humans to the moon. The leading global supplier to the space industry Beyond Gravity is part of the first three Artemis missions and delivers important elements for the mission’s Orion spacecrafts, the SLS launch vehicles as well as the planned Gateway space station.

For the first time since 1972, humans will land on the moon thanks to the Artemis missions. Later, a new space station (gateway) will orbit the moon and serve as a stopover station for astronauts and spacecraft. The Artemis 1 program will launch an empty spacecraft into lunar orbit as a first step, the second mission will already be crewed, and in the third mission, four astronauts is expected to set foot on the moon in 2025 for the first time in more than 50 years. Closely associated with the Artemis missions is the SLS (Space Launch System) launch vehicle. It will carry the Orion spacecraft. Be- yond Gravity is supplying key elements for all Orion spacecraft as well as for the SLS launch vehicles.

“We are proud and honored to be part of these historic mis- sions, contributing to the progress of humanity,” said André Wall, CEO of Beyond Gravity. “Our employees in Switzerland, the USA and Austria have been developing, manufacturing and testing for the success of these missions for many years.”

Mechanisms from Beyond Gravity drive the solar wings

“Our mechanisms have to perform particularly complex and extremely precise movements to position the solar array panels correctly for all three Artemis missions. The work for this was done in Zurich, Switzerland,” says Anders Linder, head of satellite business at Beyond Gravity. What is special about the mechanisms is that it must be possible to fold the solar array panels in such a way that they are not damaged when the propulsion system fires. This is due to the fact that the European Service Module (ESM) from prime contractor Airbus has its own propulsion system.

In addition, Beyond Gravity’s knowledge in carbon fiber composite manufacturing is helping to produce a large connector (universal stage adapter) that links the launch vehicle and the service module. “Work on this adapter started back in 2017 and was done at the U.S. facility in Decatur, Alabama. We did the design analysis and production at our plant in the U.S.,” added Holger Wentscher, head of the launcher business at Beyond Gravity. The adapter is 9.9 meters high and 8.4 meters in diame- ter at its widest point. The adapter from prime contractor Dynetics will be used for the first time on the second Artemis mission.

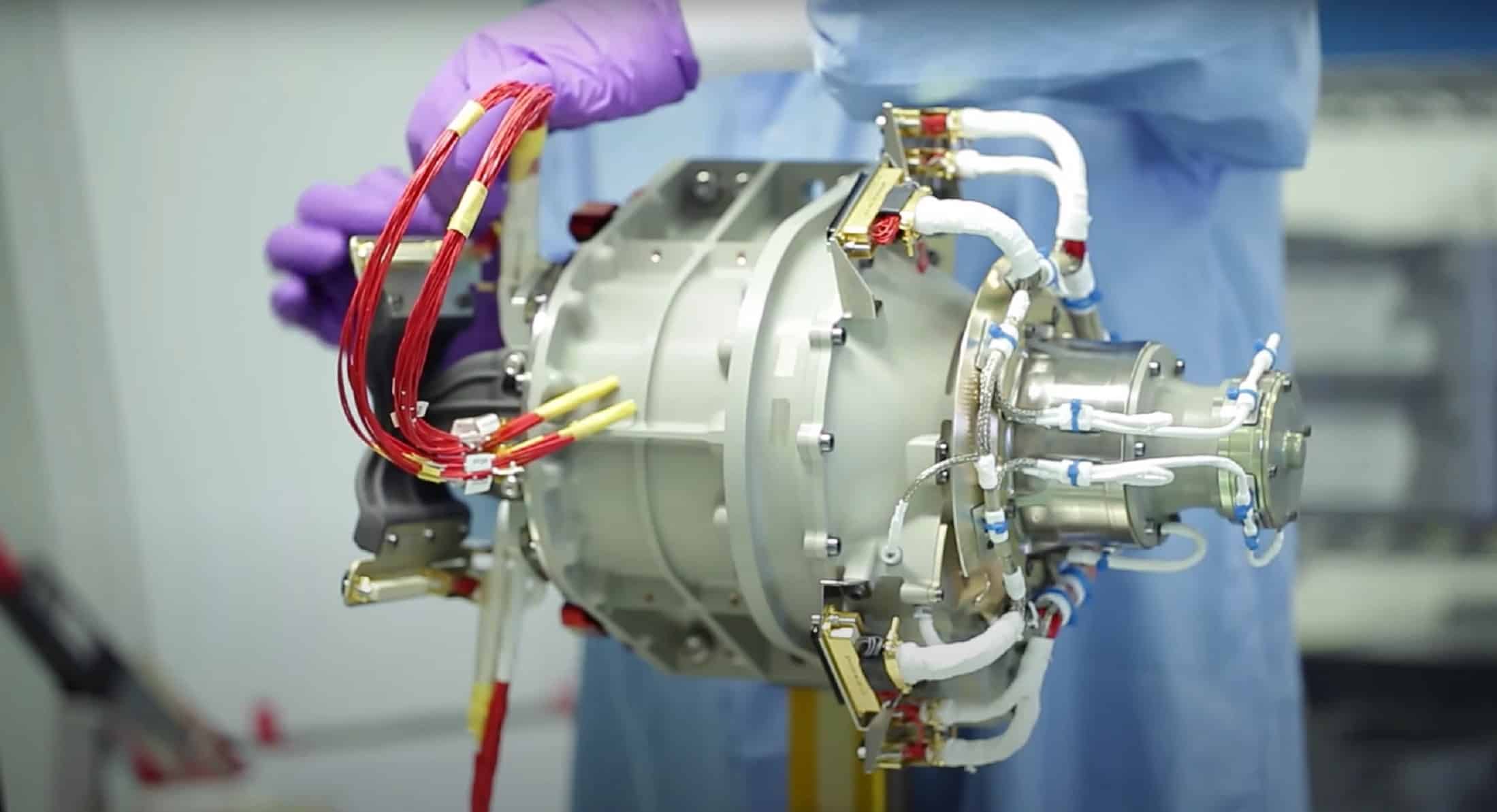

Network electronics from Austria for new space station

Together with its partner TTTech, Beyond Gravity is supplying the central network electronics for the NASA Gateway, which will guarantee secure and reliable communications between Earth and the space station. US satellite manufacturers Maxar and Northrop Grumman will integrate the products into the gateway, which will orbit the moon as a manned space station at a distance of over 400,000 kilometers from Earth and serve as a stopover for astronauts and spacecraft.